Working principle of drum screen:

● The drum screen rotates the drum body to make the garbage tumble in it and separate it according to the particle size. Materials of different sizes will fall into the corresponding collection device through different apertures on the screen surface to achieve classification.

● The screen surface is usually made of woven mesh or perforated thin plate, and the screen body will be installed at an angle. When working, particles smaller than the size of the screen hole will fall through the screen hole, while particles larger than the size of the screen hole will be left in the drum and discharged from the other end as the drum rotates.

Trommel Screens mainy to the city garbage ,filling garbage ,urban garabage ,waste metal etc sorting industries . to sort the hard material from inert material via size or density .

Different kinds of material uses different type of the trommel sreens for the rotary or inner hexagon screen.

appliance : living waste , filling trash , metal scrap etccharacters :

different size of material will be sorted by different hole diameter of screen .

To sort the origanic matter from others .

Designed by modular type which is easy and convenient to repair or maintain to improve the working efficient.

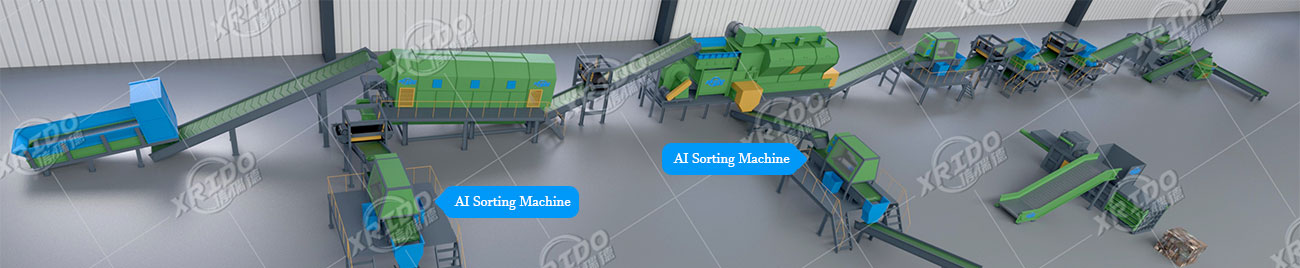

We can design the most suitable waste sorting recycling process according to your materials for free.

√Domestic Waste, Urban trash; √Landfill Stale Waste; √Municipal Solid Waste; √Construction and Demolition Waste; √Scrap Metal, Industrial Waste; √Plastic Waste, Solid Waste

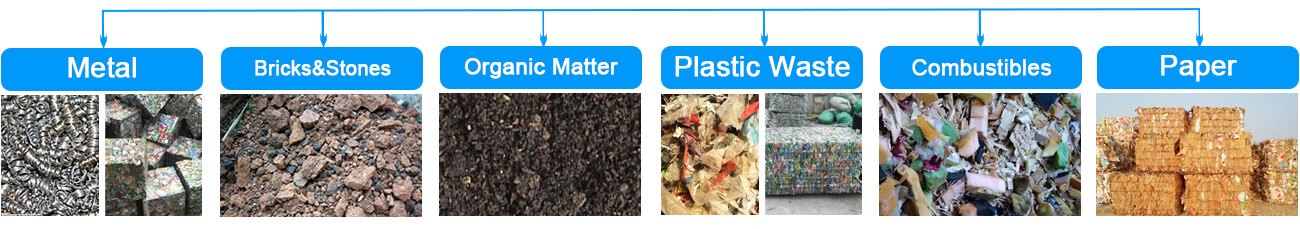

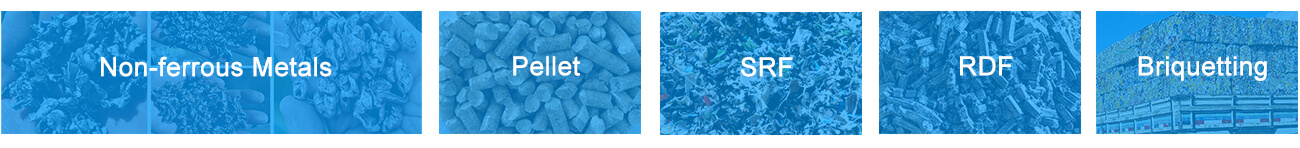

The waste sorting line can separate the plastic, waste paper, metal, glass, combustibles, wood, organic matter, bricks and stones from the material.

| Screen Diameter | Screen Length | Rotating speed | Capacity | Broken bag rate | Screening rate | Power |

| (mm) | (m) | (r/min) | (t/h) | (%) | (%) | (kw) |

| 1200 | 4-5 | 0-20 | ≥20 | 60-90 | 70-90 | 4-5.5 |

| 1500 | 5-9 | 0-17 | ≥40 | 60-90 | 70-90 | 5.5-7.5 |

| 1800 | 6-10 | 0-14 | ≥50 | 60-90 | 70-90 | 7.5-11 |

| 2000 | 8-11 | 0-13 | ≥60 | 60-90 | 70-90 | 11-15 |

| 2200 | 9-12 | 0-12 | ≥70 | 60-90 | 70-90 | 15-18.5 |

| 2500 | 10-15 | 0-11 | ≥80 | 60-90 | 70-90 | 18.5-22 |

| 3000 | 10-15 | 0-11 | ≥100 | 60-90 | 70-90 | 22-30 |